About Us

Hi-bond Bearings Pvt. Ltd quickly became the much sought-after

developer, producer and supplier of a wide range of high-quality

bearings and bushing for the mechanical engineering and

manufacturing industries. It became the go-to company for the very

finest plain shaft engine bearings and bushing. The 1990s brought

steady growth and recognition to Hi-bond as one of the very best in

its segment – a position and responsibility that the Patel family

strives to maintain to this day.

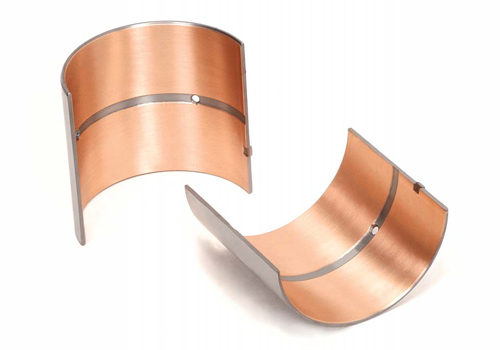

Now, with over a 100 employees, and a 2,400 square metre state-of-the-art manufacturing plant in Rajkot, Hi-bond Bearings Pvt. Ltd has established itself as a leading producer of thin-walled and thick-walled bi-metal and tri-metal bearings, bushings, and thrust washers. These products are used for a variety of products – cars, trucks, tractors and other automobiles; compressors, gas turbines, earth movers, pumps, agricultural engines, diesel engines, railway engines, marine, and other heavy-duty engines. The production of consistently high quality materials, on-time delivery, affordable pricing, and a robust sales network has made Hi-bond an internationally recognisable name in over 30 countries, including the UK, Europe, North and South America, the Middle-east, Far-east, Asia Pacific and Russia.

The story of Hi-bond is the story of success through tireless dedication and excellence. Over 30 years of experience has paved the way to the leading position Hi-bond commands in the manufacturing market today. Hi-bond an ISO 9001-2008 Certified (by German Independent Testing Lab TUV) company, that runs like a well-oiled machine, delivering perfection and precision in manufacturing. Hi-bond Bearings Pvt. Ltd will continue to innovate and push the boundaries of bi-metal and tri-metal manufacturing to deliver the very best for their ever-expanding roster of clients.

Now, with over a 100 employees, and a 2,400 square metre state-of-the-art manufacturing plant in Rajkot, Hi-bond Bearings Pvt. Ltd has established itself as a leading producer of thin-walled and thick-walled bi-metal and tri-metal bearings, bushings, and thrust washers. These products are used for a variety of products – cars, trucks, tractors and other automobiles; compressors, gas turbines, earth movers, pumps, agricultural engines, diesel engines, railway engines, marine, and other heavy-duty engines. The production of consistently high quality materials, on-time delivery, affordable pricing, and a robust sales network has made Hi-bond an internationally recognisable name in over 30 countries, including the UK, Europe, North and South America, the Middle-east, Far-east, Asia Pacific and Russia.

The story of Hi-bond is the story of success through tireless dedication and excellence. Over 30 years of experience has paved the way to the leading position Hi-bond commands in the manufacturing market today. Hi-bond an ISO 9001-2008 Certified (by German Independent Testing Lab TUV) company, that runs like a well-oiled machine, delivering perfection and precision in manufacturing. Hi-bond Bearings Pvt. Ltd will continue to innovate and push the boundaries of bi-metal and tri-metal manufacturing to deliver the very best for their ever-expanding roster of clients.

.png)